SINOMA

BUSINESS SCOPE

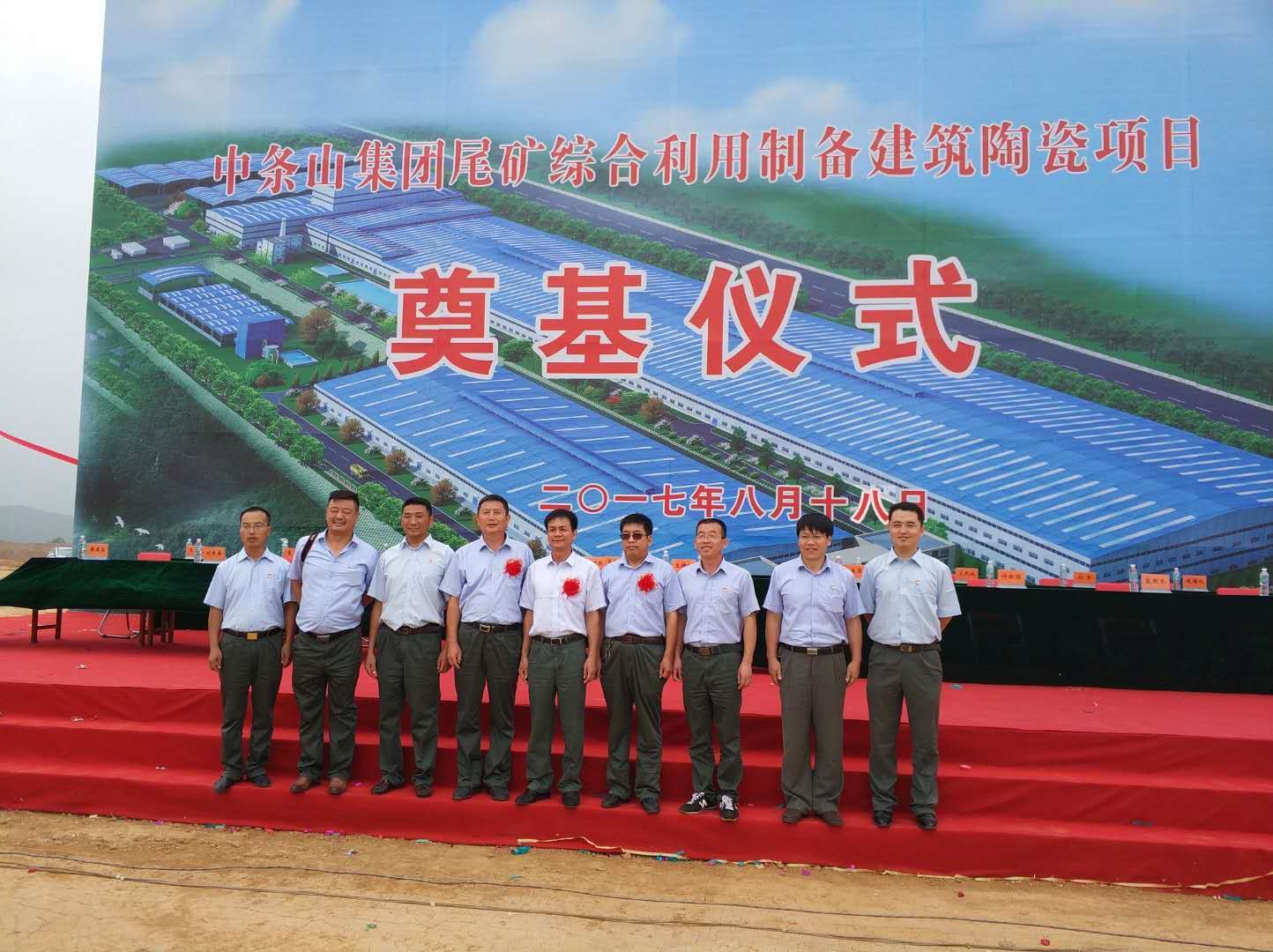

Preparation of architectural ceramics project for comprehensive utilization of Zhongtiaoshan tailings

The comprehensive utilization of tailings to prepare architectural ceramics project is the key project of the “Thirteenth Five-Year Plan” for the transformation and upgrading of Zhongtiaoshan Group. I

Product Classification:

Building materials project

Key words:

Preparation of architectural ceramics project for comprehensive u

Detailed introduction

Design concept of comprehensive construction of building ceramics project in Zhongtiaoshan tailings

The comprehensive utilization of tailings to prepare architectural ceramics project is the key project of the “Thirteenth Five-Year Plan” for the transformation and upgrading of Zhongtiaoshan Group. It is based on the efficient and comprehensive utilization of resources and recycling, with “reduction, reuse and resource utilization” as the core. Purpose, an economic growth project that achieves the concept of sustainable development. The total investment of the project is 630 million yuan, including construction investment of 560 million yuan. An inner wall brick production line and a full-glazed floor tile production line will be built, with an annual output of 20 million square meters of wall and floor tiles. It is planned to be completed and put into operation in the second half of 2018. At that time, the annual sales income will be 420 million yuan and the total profit will be 55 million yuan.

The project has several technical innovations in its design:

The first is the efficient and comprehensive utilization of resources. In the country, we took the lead in mastering the core technology of tailings and ceramics, and applied for 2 national invention patents. The high proportion of tailings addition is of great significance for extending the service life of tailings ponds and sustainable production of mines.

Second, advanced technology. The use of mature and multi-breaking and pre-crushing and continuous grinding production processes in the mining and smelting industry, the new wide-body kiln firing technology and the kiln waste heat utilization technology have changed the drawbacks of the extensive production of the ceramic industry in the past and effectively saved energy.

Third, the degree of automation is high. In 2015, it first proposed the automation concept of intermediate storage and delivery and sorting of blanks. It was adopted by ceramic equipment enterprises and guided the development of corresponding equipment, which effectively improved the automation level of ceramic production lines, reduced labor intensity, reduced staff and efficiency. The effect is obvious.

The fourth is the green environmental advantage. The environmental protection measures invested more than 19 million yuan, and the raw material area adopts a closed factory building, which effectively avoids the dust pollution to the surrounding environment. The dry mist suppression, fog gun and dust collector are set in the raw material workshop to reduce the dust pollution in the production process and adopt multiple areas. The independent water treatment system and the centralized desulfurization and denitrification arrangement of the whole plant can realize zero discharge of production wastewater, discharge of exhaust gas and discharge of waste residue, and fully comply with the current national environmental protection standards. It has played a leading role in environmental protection model and set a benchmark for enterprises in the ceramic industry and surrounding areas.

Related Business